-

Machine Guarding

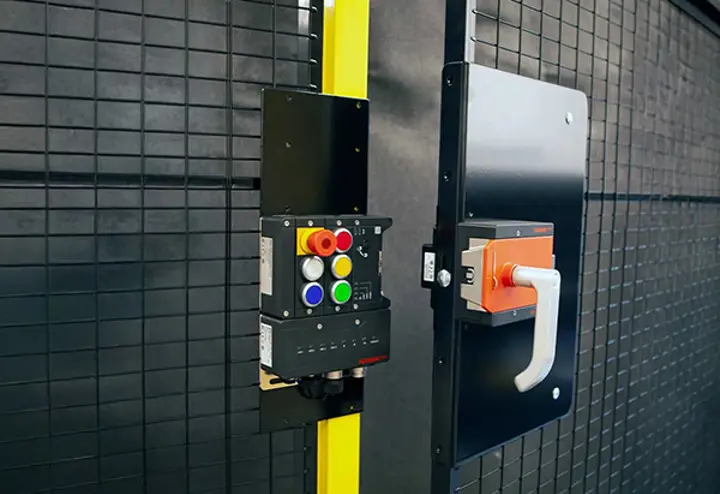

Machine guarding

Axelent is a market leading manufacturer of machine guards. The complete system that we deliver meets current safety directives and standards.

-

Warehouse

Axelent's market’s leading industry and warehouse storage products.

Discover smart solutions for creating partitions, secure cages, and to protect against falling goods and pallets from racking.

Partitions and cages

Pallet & Falling Goods

Fall protection System

Mesh shelving

Services

-

Impact

Impact protection

X-Protect is Axelent's range of impact protection. We offer all impact protection you need, from bollards to safety barriers, column guards and pedestrian barriers.